|

1550Z-AL Die Casting

1550-AL Die Casting

1590-AL Die Casting

1590 Stomp-AL Die Casting

1590 Rib -AL Die Casting

RP-Sealed

RP-Sealed 的複本

RS-Sealed

RZ - Sealed Enclosures

RW-Wiring

RG-Cable Glands

RM-Instrumental

RA-AL Extrude

RH-Hand-Held

RH / Hand-Held

RL-Project Box

RL-Project Box

1553 Soft Side Hand Held

1553 Soft Side Hand Held

1591 Small Project Box

1593 Hand Held

CUSTOMIZATION

1593HAM

1596 Potting Box

| |

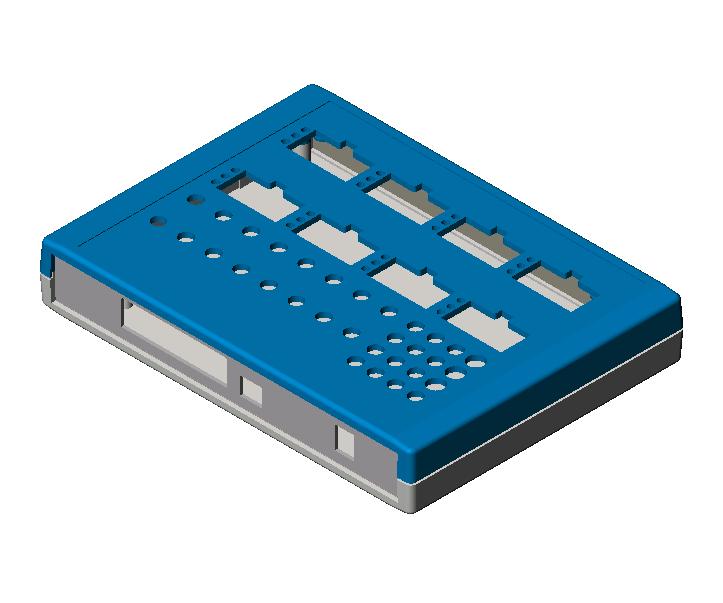

RM series

Instrumental enclosures

|

CUSTOM MODIFY ENCLOSURE

|

|

.

UL

flame retardant material molded.

ABS

Flame

Retardant (UL-94V0)

.

.

Temperature Rate -

ABS

: -40℃

~ +75℃

.

Full unit supplied in same color as light gray color as standard color.

.

Four parts assemblies as top cover, bottom cover and front, rear

panels.

|

|

|

.

Top Lid designed with a interchangeable insert for quantity production

applications. This rectangle area could be modified to meet any custom

designing cutout opening and smooth recessed for custom label, membrane

switches or silkscreen printing custom logos and graphics directly.

.

Three different front and rear panel offered various electronic devices requirements.

a,

ABS smooth panel - easy to be machined like drill, mill, punch to make

opening for connectors, switches, etc.

b,

Infra-Red panel - dark red transparent PMMA material mold for infra-red

sensor or receiver, LED display moudules.

c,

Aluminum panel - anodized aluminum panel offer a strong construction or

any devices need grounding application.

|

|

SIZE

(

L x W x H )

|

ABS

UL-94V0

|

|

130

x 100 x 30mm.

|

RM2015S

|

|

130

x 100 x 50mm.

|

RM2015M

|

|

130

x 100 x 70mm.

|

RM2015L

|

|

190

x 140 x 30mm.

|

RM2055S

|

|

190 x 140

x 50mm.

|

RM2055M

|

|

190

x 140 x 70mm.

|

RM2055L

|

|

250

x 180 x 50mm.

|

RM2095S

|

|

250

x 180 x 75mm.

|

RM2095M

|

|

250

x 180 x 100mm.

|

RM2095L

|

|

**

Option: IR – Infra-Red dark red PMMA

transparent front Panel.

AL –

Anodized Aluminum Panel.

|

FT

– All sizes are available for Stand Feet .

|

Secondary Operate service:

•Machining: Drilling, Milling, Punching for

custom cut-out opening.

•Printing:

Silkscreen printing, Painting.

•Modification:

Top cover, front and rear panels have interchangeable insert could be modified by custom cut-out opening

for quantity production.

•Custom

material and custom color are available up on request.

Custom OEM and ODM enclosure projects are available up on request.

|